[AI171] A technically sound, logically deduced, respectfully nuanced, plausible root-cause-of-accident hypothesis.

- Prashant Kavi (PK)

- Jun 26, 2025

- 13 min read

Updated: Jul 27, 2025

In recent days, an interesting hypothesis to explain the probable reason of the AI171 crash has been widely circulating on social media. It started as a comment on a YouTube channel and has quickly gained traction, as a well-analyzed, technically sound and a highly plausible scenario based on the limited current (visual) evidence. We do not know the precise identity of the theorist yet, who is only identified by his rather deceptively titled and dormant YouTube channel nom de plume: @HeyFixThis.

However, the theory (originally shared by a friend, a widebody pilot who's flown the B787 and therefore verified in good measure) clearly indicates that it originates from an expert with substantial inside knowledge of the B787 systems, particularly Avionics, suggesting that this individual could likely be a maintenance specialist.

While also being in the realm of speculation, yet what separates this theory from most of the rest is its objective and detailed technical analysis, nuanced presentation of the facts and importantly, zero sensationalism. All of which presents a compelling and well-reasoned hypothesis (and one must re-emphasize here, based on just the currently available visual evidence), which seems to validate many of the observed anomalies.

So according to @HeyFixThis, the probable cause [for loss of thrust on both engines at take-off], "... was a combination of Fuel Shutoff Valve (FSOV) activation due to a cascading electrical system failure". And given the esoteric nature of the hypothesis, AVIATHÈQUE attempts to examine and break it down into a simplified explanation for lay understanding, alongside its verbatim reproduction.

DISCLAIMER: this effort should not be seen as an endorsement but simply as a well-intentioned attempt to bring into the public discourse, an insightful hypothesis, which despite being speculative is deserving of attention and academic discussion. In doing so, AVIATHÈQUE remains bound by its ethos of authenticity, objectivity and integrity, besides reaffirming its commitment to awaiting the eventual outcome of an official investigation, now underway.

Probable Cause

[@HeyFixThis]

"I believe the cause was a combination of Fuel Shutoff Valve (FSOV) activation due to a cascading electrical system failure. It’s not the first time a 787 has experienced electrical cascade system failure during the first minutes in flight and required RAT deployment. Let me explain my reasoning:

On the Boeing 787, the engines will keep running even if all hydraulic systems fail. Each engine has its own FADEC (Full Authority Digital Engine Control), powered by a Permanent Magnet Alternator (PMA) that’s driven by the engine itself. Once the engine is spinning, the FADEC operates independently — controlling fuel, thrust, and safety — with no need for aircraft hydraulics or external electrical power. A simultaneous FADEC failure is extremely unlikely."

[AVIATHÈQUE]

In the context of this hypothesis it also needs to be understood upfront, that the Boeing 787 is a clean-sheet design, which is to say that it was designed fresh and incorporated new technologies along with extensive use of composite materials, which in some cases was radically different to other Boeing commercial airplane models produced until then.

On the Boeing 787, the engines will keep running even if all the systems that move parts like the landing gear or flaps stop working. This is because each engine has its own special control system (FADEC), similar to how a car’s engine is managed by a computerized system viz. the ECM or Engine Control Module. The 787 utilizes Permanent Magnet Alternators (PMAs), essentially electricity generators, as a primary source of electrical power for its engine control systems. Two PMAs, one for each engine, are crucial for providing a reliable and efficient power supply to the aircraft's Electronic Engine Control (EEC). These controls are powered directly by the spinning engine, like a windmill generating its own energy. Once the engine starts, it can manage itself without needing help from the plane’s other systems. For instance, even if the plane loses all its electrical and hydraulic power, the engine’s control system can still decide how much fuel it needs or adjust its thrust. It is extremely rare for both of these systems to fail at the same time.

The FSOV

[@HeyFixThis]

"So, why did the engines shut down if they are supposed to be so resilient? There is one important component that can override the FADEC: the FSOV. This spring-loaded fuel shutoff valve is not powered by the PMA, but instead by the aircraft's electrical DC system. If power is lost, the spring closes the valve instantly, cutting off fuel to the engine. FSOVs are a fail-safe, designed to protect the airframe, not the engine. In Boeing’s logic, it's safer for the engine to shut down than to keep feeding fuel into a potential fire."

[AVIATHÈQUE]

According to @HeyFixThis, the engines stopped working because of a device called the FSOV, or Fuel Shut-off Valve and this forms the crux of this hypothesis. The FSOV can be thought of as a faucet that controls the flow of water to a garden hose. When this valve is triggered, it cuts off fuel to the engine, just like turning off the faucet stops water flow. The FSOV is controlled by the plane’s electrical system. It has a spring mechanism that acts as a backup safety feature. If the plane loses power, this spring automatically shuts the valve, cutting off fuel to prevent any potential danger, such as fire or damage. It is like, a home's smoke alarm could also instantly shut off the gas line during a fire—that’s the kind of safety logic at work here. While the engines are designed to keep running independently of the plane’s other systems, this valve has the authority to stop them if something seems unsafe. The idea emanating from the manufacturer's (Boeing) design philosophy is to protect the airplane first, even if it means shutting down the engines temporarily to avoid greater risks.

The Landing Gear

[@HeyFixThis]

"In the video footage, the truck tilt actuator is in the forward position (toes down). This movement requires a hydraulic system force to overcome the wind and gravity. This forward position only happens when the landing gear retracted sequence is initiated by the pilots.

The strange thing is that it is only the second step of the main gear retraction sequence to tilt the wheel truck forward. The first step is to open the doors, and if the doors are fully open, the next step is to tilt the wheel truck. It’s unclear why the doors are closed but the truck already tilted forward. Most likely the pilot selected “gear up,” which triggered the retraction sequence. The truck tilt was initiated as step 2, but the doors didn’t open due to power or hydraulic failure, or the sequence froze mid-process. The aircraft lost main power (hence the RAT), and the sequence halted with the gear in a partially commanded state: truck tilted, doors closed, gear extended."

[AVIATHÈQUE]

Ostensibly based on the couple of AI171 accident videos in circulation, @HeyFixThis points to an observation on the landing gear of the aircraft, where the truck tilt actuator—the part that tilts the airplane’s landing gear—moving forward and pointing downward. Which therefore suggests that the pilots had started retracting the landing gear after take-off.

Tilting the landing gear truck forward is actually the second step in the process of stowing the landing gear. The first step is opening the gear doors to make space for the wheels, but in this case, the gear doors stayed shut. It’s likely the gear-up lever was selected to retract the landing gear, triggering the usual sequence. First, the doors are supposed to open, and second, the gear truck tilts forward. But it seems the system froze halfway through, leaving the doors still closed while the gear truck tilted forward, as if it were preparing to go inside. This suggests the airplane might have lost power or experienced a hydraulic problem during the landing gear movement. When the main power shut off (which explains the deployment of the emergency RAT system - described ahead), the landing gear retraction process couldn’t finish properly, leaving the gear in a strange in-between state—kind of like a car stuck halfway between opening and closing its sunroof.

[@HeyFixThis]

"That gear retraction moment may have been the exact point when the whole system collapsed just 3-4 seconds after takeoff.(there was a positive climb rate at 600ft AMSL and 174kt ) The engines kept running briefly (3seconds), powered by the remaining fuel in the lines before flaming out. The main landing gear hydraulics are powered by an electric-hydraulic system — if there’s no electricity, there’s no hydraulic pressure. In contrast, other hydraulic systems on the aircraft are supplied by engine-driven mechanical pumps. (20-30kw power needed to retract gear)"

[AVIATHÈQUE]

@HeyFixThis surmises that the landing gear movement might have been the moment when everything went wrong, just a few seconds after takeoff. One can imagine the plane climbing steadily, like a car driving uphill, when suddenly the engines stop working. For a brief moment, the engines were still running because there was leftover fuel in the lines, but soon after, they ran out and shut down completely. The plane's landing gear needs hydraulic power to move, which is sort of like how a jack lifts a car when changing tires—it requires a strong tool powered by some force. In this case, the main landing gear relies on electricity to provide that force. Without electricity, the hydraulic system can't work, meaning the landing gear is stuck. Other parts of the plane use pumps attached to the engines to keep working, but for the landing gear, no electricity meant no movement.

The Ram Air Turbine (RAT)

[@HeyFixThis]

"Since the aircraft remained stable in flight, it's likely that both engines flamed out simultaneously. Flaps, fly-by-wire, landing gear, and other systems likely froze for a moment and possibly regained functionality after the RAT deployed. The +-15kW RAT powers the electric motors on the blue hydraulic lines of a 787. This controls the key flight-control actuators for the rudder, elevators, and primary ailerons. It appears that the pilot slightly increased the nose attitude during the final phase of the flight. (landing gear retraction is not possible with a RAT)"

[AVIATHÈQUE]

When both engines stopped working, the plane remained steady in the air for a while. Systems like the flaps, landing gear, and other controls might have briefly stopped working too, until they kicked back into action with the help of the Ram Air Turbine (RAT). RAT is like a wind-powered generator that steps in when the main power goes out—it provides just enough energy to keep critical controls functioning. For example, it powers the control, surfaces on the wings and the tail which help maneuver the plane and keep it flying. In this case, the pilot may have slightly lifted the nose of the aircraft during the last moments of the flight, possibly trying to keep the plane stable. However, without the usual power systems working, things like retracting the landing gear weren’t possible because they require more electricity than the RAT can produce.

Massive Electrical Failure

[@HeyFixThis]

"For both FSOVs to close, the aircraft would have to lose both AC buses, both DC essential buses, and the battery backups. That requires a massive electrical failure to overcome all possible redundancy layers. This is a possibility because there are known cases where a 787 and a 777 experienced a total electrical cascading failure of most systems. So it is possible.

All signs point to fuel cutoff via the FSOVs. The big question is why did they fail? This is hard to say but as said electrical failure is a very plausible cause."

[AVIATHÈQUE]

@HeyFixThis explains, that for the Fuel Shut-off Valves (FSOVs) to stop working, the plane would need to lose power in several key systems all at once, including its main electrical sources, backup systems, and emergency batteries. Akin to a house during a total blackout; not only do the lights go out, but even the emergency lights fail too, leaving no way to see or operate anything. This kind of widespread power loss is extremely rare, but it has happened before in some airplanes, such as the Boeing 787 and 777, which experienced total electrical failures that affected most of their systems. These incidents show that such a breakdown is possible, though very unlikely. In this case, it seems that the fuel to the engines might have been cut off because the FSOVs stopped working. The big question is why those valves failed. Electrical problems seem to be a likely explanation, as the plane relies heavily on power to operate these systems.

RAT Deployment Risk (during power transition events)

[@HeyFixThis]

"The RAT was automatically deployed. This means there is a total loss of AC electrical power.

I suspect a scenario where a partially working or unstable electrical system triggers RAT deployment amid a power transition event. This could escalate into a full-blown electrical disruption, possibly interfering with the DC essential buses and battery backup. When switching power sources (from main buses to RAT), the system can behave unpredictably — especially if one source is competing with the RAT or is unstable. In such a power chaos, RAT deployment might introduce transients or delays in power restoration, which could make power delivery unstable and possibly affect the digital managed power to the FSOVs. If they lose power, all fuel will be cut off."

[AVIATHÈQUE]

The RAT as previously described, is like a backup wind-powered generator that kicks in when the plane's main electrical system completely fails. In this situation, it was deployed automatically, dropping down from its housing on the underside of the plane just behind the main landing gear. This implies that that the plane had lost all its primary sources of electricity. This can be likened to switching between backup power sources at home during a blackout—say, moving from a generator to battery-operated emergency lights—and for a moment, the lights flicker or go out completely while the transition happens. Something similar may have occurred here, where the plane's electrical system tried to switch to the RAT, but the process was shaky or unstable with a lag. This might have caused disruptions in how power was distributed across the plane's systems. During this confusion, the parts responsible for controlling the fuel flow to the engines—the FSOVs—could have lost power altogether. And as explained previously, if the FSOVs stop working due to lack of power, the result is that fuel gets cut off entirely, and the engines stop running.

Power management software

[@HeyFixThis]

"On the 787, FSOVs don’t have guaranteed dedicated or hot battery backup, unlike the Airbus A320, which powers them directly from the battery. The 787’s battery backup supports the entire DC bus, and power management software prioritizes flight-critical systems. If power is limited or loads are erratic, less critical systems like FSOVs can be deprioritized. This is a very complex system with a lot of software rules."

[AVIATHÈQUE]

On the 787, the system that controls the fuel shutoff valves doesn’t have a dedicated backup battery like some other planes, such as the Airbus A320. Instead, it shares the backup battery with many other systems. It's just like as if your phone’s battery had to power your phone, tablet, and laptop all at once—if there isn't enough power, the less important devices might shut down first. Similarly, on the 787, the software decides which systems get priority when power is limited, and the fuel valves might not make the cut if the system is struggling to keep up. This setup is particularly intricate because the plane relies on software to make these choices, which can sometimes lead to unexpected problems.

Boeing's design philosophy

[@HeyFixThis]

"This also reflects Boeing's design philosophy: in a severe power failure, airframe survivability and flight control take precedence over engine continuity. Their assumption is that it’s safer to shut off fuel than risk uncontrolled flow in to an engine on fire. The whole idea of the possibility of losing both engines at 400 ft during takeoff feels inherently unsafe. From a thrust continuity perspective, this design approach is a vulnerability and may have played a role in Flight AI171’s dual-engine flameout. To date, there are no documented cases of a modern Boeing experiencing a engine flameout from FSOV closure due to an electrical glitch. The 787 and other Boeing models have a history of similar electrical issues."

[AVIATHÈQUE]

A reflection of Boeing's design philosophy: in situations where the power system fails badly, they prioritize keeping the aircraft stable and controllable over ensuring the engines keep running. The logic being that it’s safer to cut off fuel flow completely than risk fuel feeding an engine that might be on fire. Like a car, where the fuel pump is automatically shut off if there’s a risk of a fire under the hood. The problem here is that losing both engines during takeoff, when the plane is only a few hundred feet off the ground, feels incredibly risky. The decision to prioritize control systems over engine operation could create unsafe situations, like what may have happened with flight AI171, where both engines stopped working. So far, there is no precedence of any Boeing models losing their engines completely because of fuel valves shutting off due to electrical problems. However, Boeing planes like the 787 have had other electrical issues in the past. To simplify with an analogy, it’s like your phone suddenly shutting off because its battery struggles to split power between too many apps.

Past incidents

[@HeyFixThis]

"In 2024 an Atlantic Boeing 787 flight, VS105 during climb-out, the crew experienced a major electrical failure— engine generators dropped off-line. In response, the RAT automatically deployed to provide emergency power.

In 2015, Boeing and the FAA discovered a critical software bug in the 787’s Generator Control Units (GCUs). If left powered for 248 consecutive days, an internal counter could overflow — shutting down all four GCUs and cutting AC power entirely. The FAA issued Emergency AD 2015-08-51, requiring operators to reboot 787s every 8 months to avoid in-flight total power loss.

Two separate incidents—in Boston (JAL) and Takomatsu (ANA)—involved battery overheating and fire in the aircraft’s APU lithium-ion batteries.

In December 2018, LATAM Flight LA8084, a Boeing 777-300ER, suffered a complete electrical meltdown enroute from São Paulo to London. The RAT deployed to provide emergency power. Once the engines were shut down on the ground, power suddenly returned — confirming a fault in the electrical distribution system (likely a bus contactor or converter failure). The event was a textbook cascading failure: generator power was available, but a chain reaction of breaker and converter failures disconnected all major buses, including those powered by the APU and engines.

The 787 relies heavily on software-based power management, so if the root cause turns out to be a software flaw in a extremely complex electrical system, the entire fleet could soon be grounded pending investigation."

[AVIATHÈQUE]

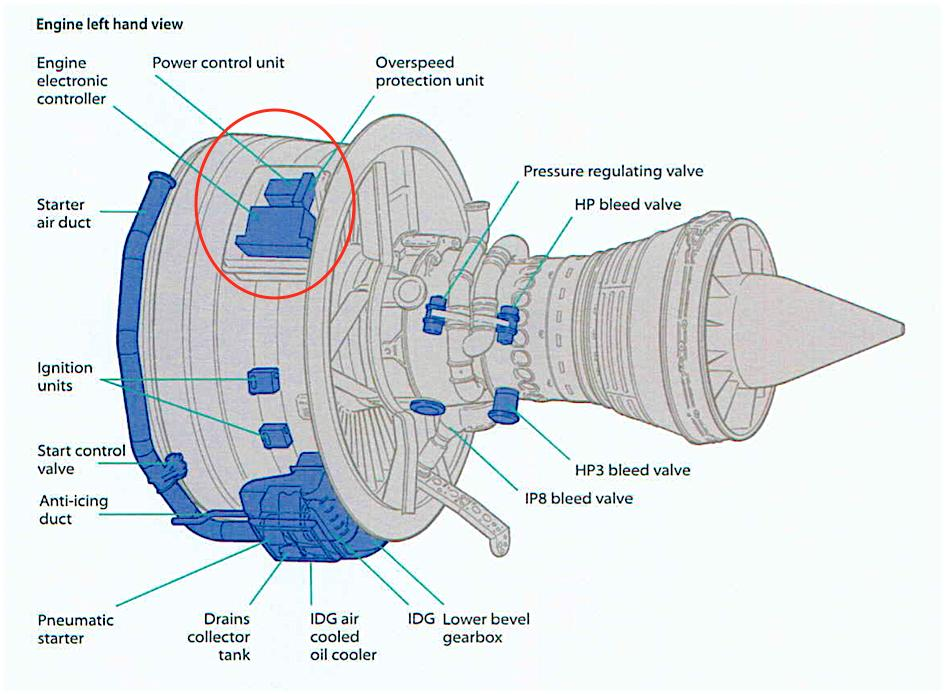

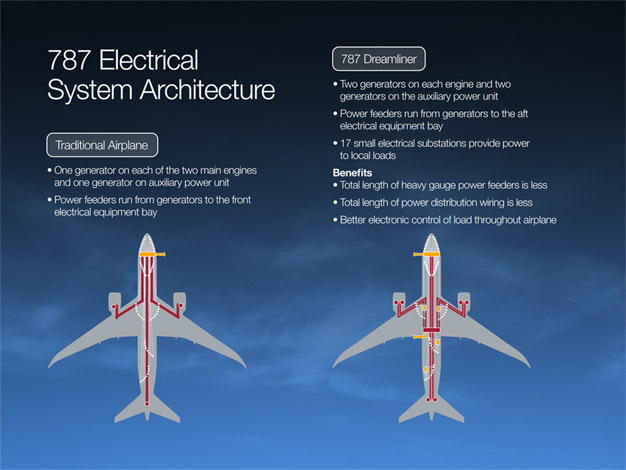

According to Boeing, the 787's Electrical System, centered around a 'more-electric' design philosophy, is a radical shift from traditional aircraft systems. Instead of relying heavily on pneumatic and hydraulic systems, the 787 uses electrical power to drive many key functions: engine start, wing anti-ice, cabin pressurization, and even some flight control actuators. This reduces weight, improves fuel efficiency, and simplifies maintenance.

But, while the 787’s 'more-electric' software-based architecture may be a marvel of modern engineering, it also concentrates risk. When electrical systems are compromised, perhaps because of a software flaw, the aircraft may lose not just convenience — but core functionality.

Author's Note

Summarily then, this hypothesis paints a coherent picture: The aircraft experiences a significant electrical system failure shortly after take-off, potentially initiated or exacerbated by the high electrical demand of gear retraction and/or a power transition event. This cascading failure leads to the loss of power to the DC essential buses and battery backups, which in turn de-energizes the FSOVs, causing them to spring-load close and cut fuel to both engines simultaneously. The RAT deploys due to the total AC power loss, restoring some critical hydraulic and flight control functions, but not the ability to restart the engines or even complete the gear retraction sequence.

The hypothesis concludes by implying, that accident Investigators would be looking into whether the problem was caused by software issues, power system transitions, or other vulnerabilities in the aircraft's complex electrical system, all of which could have potentially far reaching implications for a sizably active B787 fleet.

In continued remembrance of lives lost and impacted.

Comprehensive and plausible explanatory theory with sensible comments by Aviotheque!